News, 6 February 2026

News, 6 February 2026

Plenty to report in this update, starting with the removal of more redundant cable entry points. The two points below were originally for the traction motor cables on the donor loco. We don't need these, there being two fewer traction motors on a Baby Deltic. Also, we're clever and we've implemented the BR mod to remove half the cable runs between the control cubicle and the motors. The holes which remain will be plated over once the weather warms up - no point welding when the loco's freezing cold.

Years ago it was obvious that we'd have to do something about the parking brake and the way it's applied / released. Whilst there are broad similarities between a Class 37 and a Baby Deltic parking brake the movement of the application screw and therefore the movement of the linkages was reversed between the two types.

We went round in circles investigating spring applied brakes (very common now in rail applications), hydraulically applied brakes (less so, but, Cl. 58s / 60s / 90s / others), air applied parking brakes (HSTs) and electrically applied brakes (Cl. 66 / others) but we kept returning to the originality quest and settled on HUGE EXPENSE to have a load of new parts made.

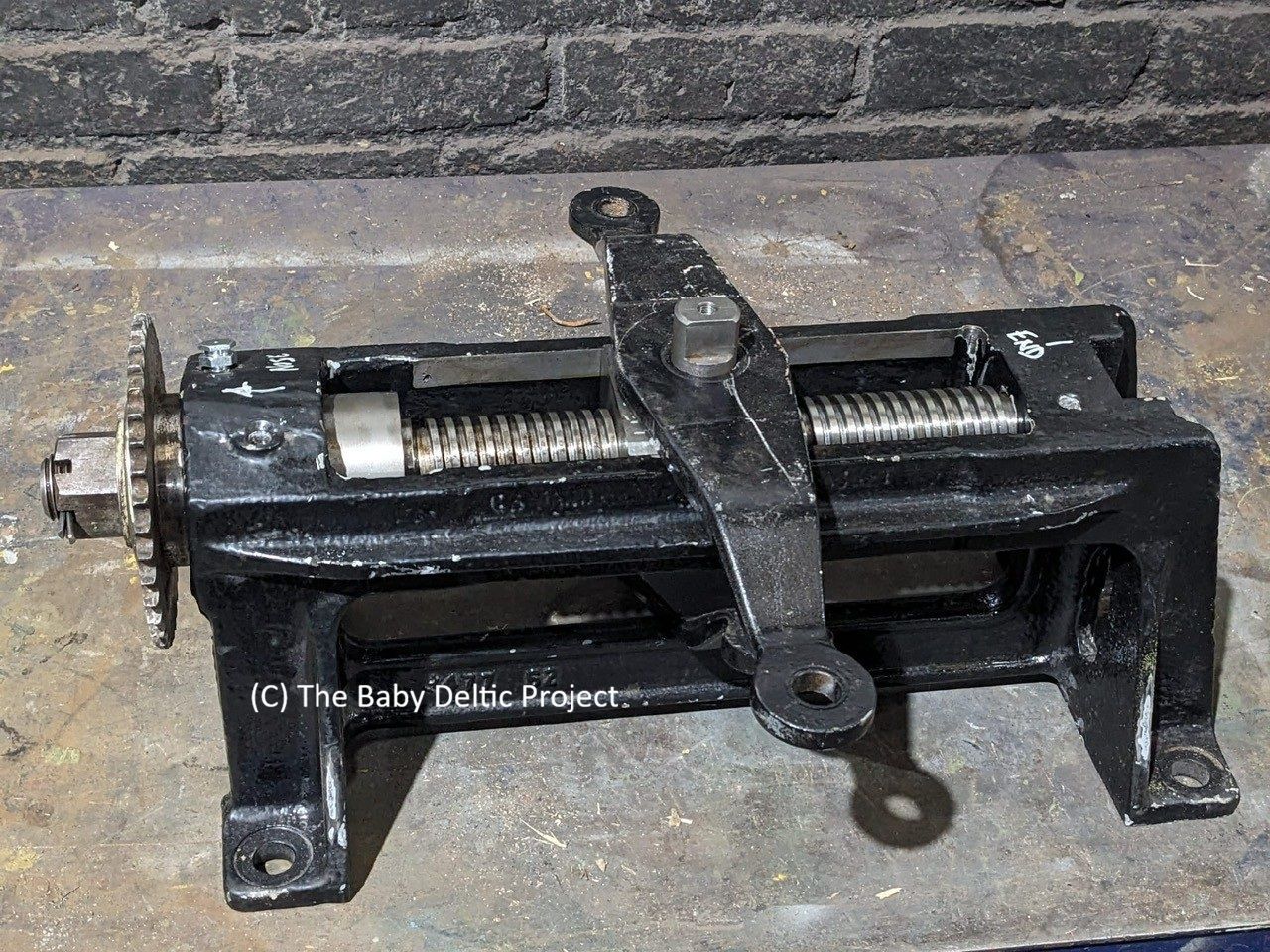

Principle amongst these were two (one for each end) new lead screws to reverse the application direction of the levers. Seen below is one of the new screws, one of the new trunnion blocks (carrying the application levers) and a new end-stop bush. What can't be seen are a new split cotter to hold it all in place and a new bronze bush and new thrust bearing the make it turn smoothly.

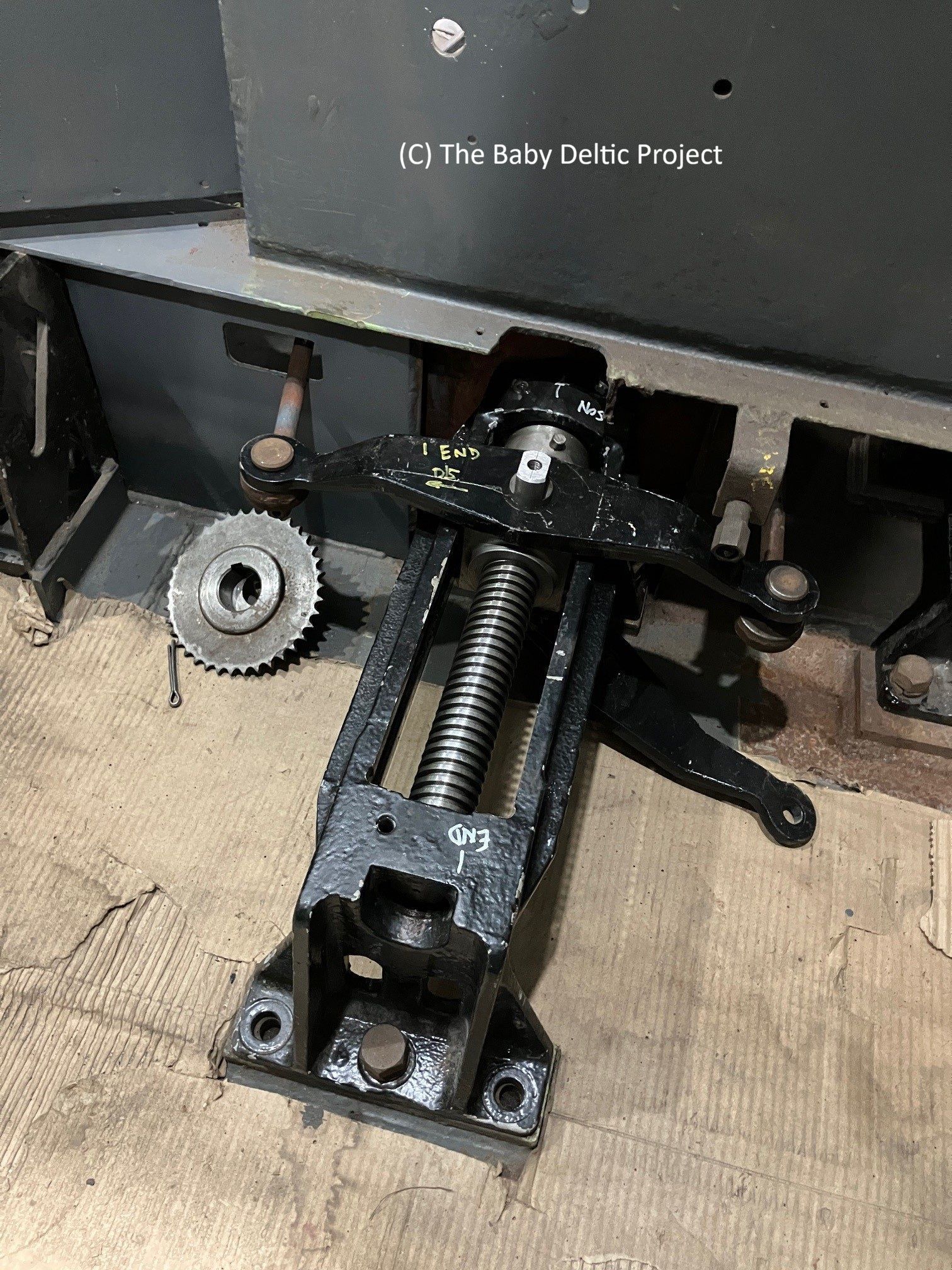

The new arrangement below shows the screw in place but not secured with (just visible attached to the lever) the two (one for each side of the loco) pull rods...

...the pull rods operate a straight lever and an angle lever (no photos of these, I forgot). The angle lever turns the pull motion through 90 degrees and then via another pull rod to another angle crank to change direction once again.

The cranks are the same as the donor loco one, just relocated.

The mechanical losses in this number of cranks are high, one of the reasons for all of the newish direct acting systems now in use on modern rail vehicles.

Finally for this update is the new brake valve control arrangement. Baby Deltics were only ever vacuum braked, our donor loco was dual braked. It makes perfect sense to have the recreated loco dual braked too, so that's what we've done.

The problem with this is that the drivers dual brake valve bears no resemblance to the original vacuum brake valve. The valve would stand out in the cab like a Polar Bear in a dinner suit trying to get into a "Penguins only" nightclub.

So we designed a brake controller which looks like the original Westinghouse vacuum brake valve but only serves to operate the dual brake valve (Westinghouse M8(A)) which is hidden below the desk. The two photos below show the new dummy and the M8(A) in their extreme positions; release and shut down. There's a universal joint / sliding joint assembly to go in yet but this is for a future update.

The wood behind the valve is only holding the quarterlight in temporarily and the M8(A) is not hidden yet. Don't write in :)